FlyAsh produced at Coal based ThermalPowerPlant, is a resource material for Cement industry and building products manufacturing units. It is also being used as one of construction material in Road and Fly over embankment construction and thus helping to save earth and degradation of good agricultural land. Sustainable FlyAshutilization is one of the thrust areas of its activities at all NTPCs Coal based PowerPlants. To give momentum for FlyAsh utilization, separate Ash Utilization Group was set up in 1991. Now, at all Coal based stations are having dedicated group responsible for Ash utilization activities and the group strives to achieve 100% Ash utilization on sustainable basis.

1.0 Efforts for Maximizing FlyAsh Utilization:

1.1 Supply of FlyAsh to Cement Industry:

To make dry FlyAsh available to users, suitable dry FlyAsh extraction and storage silos have been installed at all Coal based ThermalPowerPlants (TPPs) of NTPC. Further, to facilitate bulk transportation of FlyAsh through Railway wagons, which is presently cheapest option for bulk transportation, Rail loading facilities have been developed at Kahalgaon, Ramagundam, Rihand, Mouda, Simhadriand Korba TPS. Such system is also under installation at Sipat, Vindhyachal, Talcher-Kaniha, Solapur, Kudgi, Meja, Khargone, Lara, Darlipalli and Gadarwara TPS.

Bulk transportation of FlyAsh through Railway: To start bulk transportation of FlyAsh in closed and environment friendly manner through Railway wagons, NTPC has signed an agreement with Indian Railway under SFTO (Special Freight Train Operator) scheme and purchasedt hree BTAP wagon rakes. Now, FlyAsh supply in BTAP rakes has been started from Rihand to CementPlant located in Maihar region. FlyAsh is also being brought to demand centre like NTPC-Dadri through BTAP wagon rakes from Rihand for supply to Cement industry. NTPC Kahlgaon and Ramagundam are supplyingFlyAsh through Railway wagon rakes on regular basis to Cement industries located in North East States and Gulbarga region respectively. NTPC Mouda has dispatched FlyAsh in BCFC/ BCCW wagon rakes to CementPlant located in Gulbarga Region. Recently, FlyAsh transportation has been started in bags from Vindhyachal and Barauni TPPs also. NTPC Rihand, Mouda and Simhadri TPPs have also dispatched FlyAsh in BOXN wagons on trial basis to CementPlants and efforts are being made to start supply from these stations on regular basis.

1.2 Use of FlyAsh bricks:

To promote use of FlyAsh bricks in building construction, NTPC has set up FlyAsh brick manufacturing Plants at its Coal based ThermalPowerPlants and FlyAsh bricks are being manufactured on regular basis. These bricks are being utilized in Plant as well as township construction activities exclusively. On an average total about 60 million FlyAsh bricks are being manufactured annually by NTPCs own FlyAsh brick Plants.

As per the MoEF&CC directives, NTPC stations are keeping at least 20% of total FlyAsh produced in reserve for issue toFlyAsh brick/ blocks/ tiles manufacturers and issuing FlyAsh free of cost to them. About 9% of total FlyAsh produced in NTPCs stations, is being utilized by FlyAsh bricks/ blocks and tiles manufacturing units annually.

1.3 Supply of pond Ash for Road/ Fly over construction projects:

Ministry of Environment, Forests and Climate Changes (MoEF&CC), Govt. of India vide its Gazette Notification dated 25-01-2016, stipulates that the cost of transportation of Ash for Road construction projects within a radius of 100/ 300 km shall be borne/ shared by TPPs. The said notification also mandates that TPPsshall within a radius of 300 km bear the entire cost of transportation of Ash to the site of Road construction projects under asset creation program of Government. NTPC stations are complying to this mandate and large quantity is being supplied to NHAI/ State government Road projects through MoU route with NHAI/ State government Road construction department as well as supplying by engaging own Ash transporter through the transparent bidding procedure.

In the year 2019-20 more than 12.9 million ton Ash was supplied to various Road&Highway construction projects of NHAI/ State Governments. In the year 2020-21, 15 NTPCs station are supplying Ashto variousRoad projects and Ash utilization is expected to cross by 20 million ton.

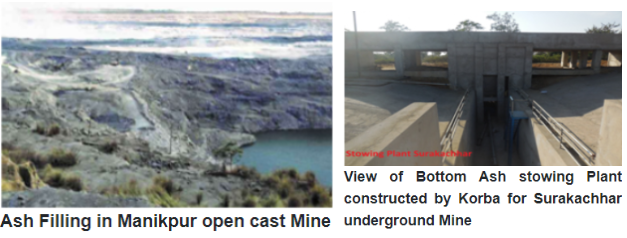

1.4 Use of Ash in reclamation of Mine Voids:

Reclamation of Mine voids using Ash is one of the area where large quantity of Ashcan be utilized on sustainable basis and reclaimed area can be developed into green land through afforestation. Reclamation of Mine void filling at NTPC Talcher-ThermalPower station has been carried out since 2005 onwards after getting due clearances from Odisha State Pollution Control Board and subsequently from Expert Committee of MoEF& CC. Station has also carried out environmental studies as directed by Expert Committee of MoEF&CC and based on the results of all studies, Committee as well as National Green Tribunal has expressed that reclamation of Mine voids can be one of the permissible avenue for sustainable utilization of Ash.

NTPC is also doing Mine void filling with Ash from its Korba TPP to ManikpurMine voids on regular basis. Further, Bottom Ash is being utilized in stowing of Surakachar underground Mine in Korba area. This activity is helping Minecompany to extract more Coal from underground Mine. At Ramagundam, Bottom Ash is being issued to Singareni Collieries Company Limited for stowing of Srirampur underground Mine. NTPC Talcher-Kaniha has also been allocated JaganathMine voids and necessary infrastructure & pipeline laying is being carried to start MineAsh filling in the voids. NTPC Vindhyachal has been allocatedGorbiMine voids for Ash filling. Environmental studies and development of infrastructure are being carried out for taking up Ash filling in this Mine void.

Ash filling along with Overburden material in Operating DulangaMine:

MoEF&CC Gazette Notification mandates for use of atleast 25% FlyAsh on volume to volume basis along with overburden material in external dump as well as upper benches of backfilling of open cast Mine. To demonstrate the use of Ash in this area, NTPC Darlipalli and NTPCs DulangaCoalMine have taken up project in association with Central Institute for Mine and Fuel Research (CIMFR), Dhanbad. Ash filling along with over burden material has been started now.

1.5 New initiatives for FlyAsh utilization

(i) FlyAsh based Geo-Polymer concrete Road:

NTPC has successfully developed FlyAsh based Geo-PolymerRoadconstruction technique and Roads were constructed at Ramagundam, Rihand, Kahlagoan, Farakka TPS for its demonstration. These Road stretches are performing well. Now, Township and CSR Road will be constructed at NTPC stations through this FlyAsh based technology forlarge scale promotion and confidence building.

(ii) To promote use of FlyAsh in Agriculture, NTPC in association with Indian Institute of Soil Science (IISS), Bhopal has taken up long term project titled “Use of FlyAsh in Agriculture for Sustainable Crop Production and Environment Protection”. The results of this study will help to remove doubts amongst agriculturist for safe and beneficial use of FlyAsh in this sector.

(iii) Setting up of Light Weight Aggregate Plant at Sipat is under progress.

(iv) Research and Development (R&D) of FlyAsh based aggregates for concrete in association with VNIT, Nagpur and SVNIT, Surat.

(v) R&D for use of FlyAsh in Gypsum Vermiculate Plaster (GVP) for internal plastering work in association with CBRI, Roorkee.

(vi) NTPC had conducted National level contest on “Grand Challenge on Ash Utilization Ideas” in the year 2018. The first winner’s idea of this contest on FlyAsh based Nano Concrete Aggregate (NACA) - a good substitute for Natural Stone Aggregate (NSA)was demonstrated by constructing 1-BHK 2-storeyed residential building at NTPC Simhadri.

1.6 Awareness and interactive meets with FlyAsh user

NTPC stations are organizing awareness program on FlyAsh utilization as well as interactive meets with FlyAsh users/ customers on regular basis for increasing FlyAsh utilization. Some of the examples are:

- In order to share information’s on various activities being carried out in NTPC as well as other Power utilities, a webinar was organized by Corporate Ash Management Group on 16-10-2020, which was participated by representatives from MoEF&CC, CEA, DVC, Tata Power, MAHAGENCO and Research Institutes like CBRI, Roorkee and VNIT, Nagpuretc.

- NTPC Barh has organized Ash users meet on 20-01-2021, which was participated by representatives from Brick/ Blocks and Cement manufacturers and officials of Road project construction department.

- NTPC Darlipalli has organized Ash users meet on 2nd Feb., 2021 to promote Ash utilizationin and around Sundergarh&Jharsuguda district of Odisha. The invitees of the Ash user meet were representatives of FlyAshBrick manufacturers of the nearby areas and Cement/ Refractory Plants of Sundergarh, Jharsuguda& nearby districts. District Industrial Centre In-charges of Sundergarh.

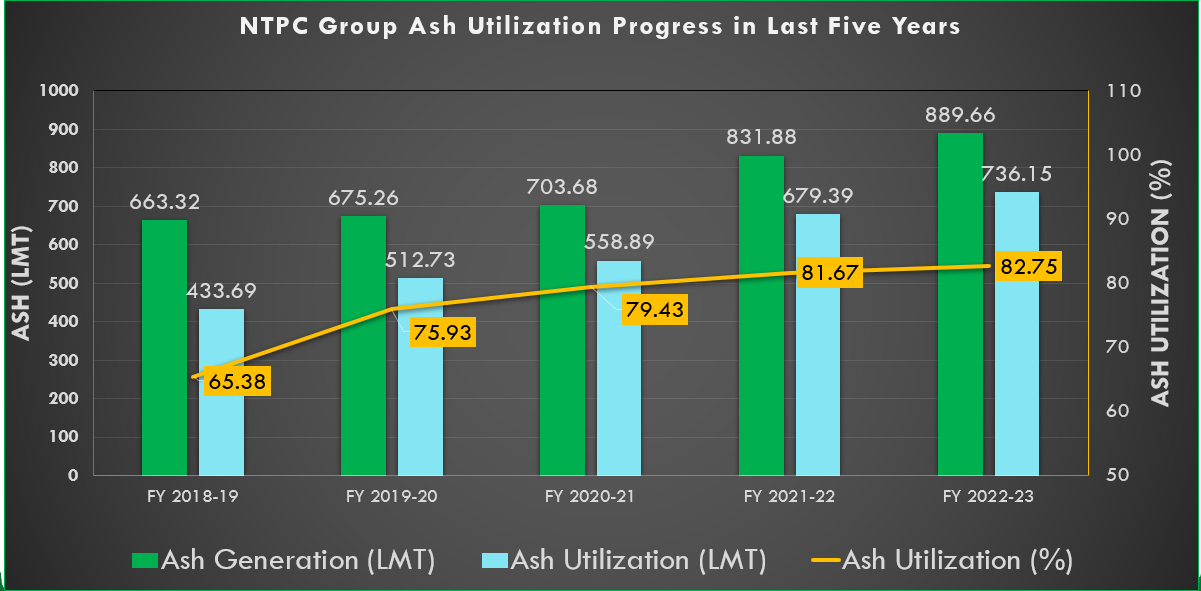

1.7 Ash Utilization progress at NTPC

The last five years Ash utilization status at NTPC are as under: