Centre for Power Efficiency & Environmental Protection

Centre for Power Efficiency & Environmental Protection was established to take initiatives to address climate change issues as well as improving the overall performance of coal-fired power plants. It was set up in collaboration with USAID and is a symbol of NTPC’s pro active and voluntary approach towards the cause of reducing green house gases emission. The centre functions as a resource centre for acquisition, demonstration and dissemination of state-of-the-art technologies and practices for the performance improvement of coal and gas fired power plants for the entire power sector of India.

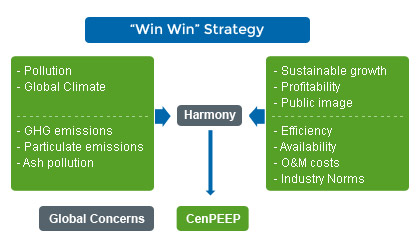

Win-win Approach for Global Climate Change

NTPC has adopted a win-win strategy at CenPEEP by achieving synergy between environmental concerns and utility needs. We have initiated the ‘Comprehensive Performance Optimisation Programme’ thereby successfully balancing the dual objectives of reducing carbon-di-oxide emissions that contribute to climate change and facilitating higher efficiency of power generation.

Underlying NTPC’s commitment to improve the overall power sector in India, CenPEEP is trying to improve the efficiency of various state electricity boards in India by demonstration and dissemination of improved technologies and practices.

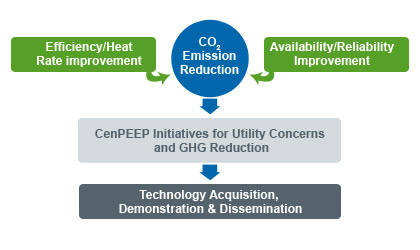

Thrust has been given to efficiency improvement through the customised ‘Energy Efficiency Management System’ (EEMS) and reliability through ‘knowledge based maintenance’. All efficiency testing guidelines are explained in details in EEMS manual.

Technological Interventions

For greater acceptability and assimilation of eco-friendly technologies and practices, methodology of ‘Technology Acquisition, Demonstration and Dissemination’ has been adopted. Our focus has been on low cost - high benefit options. We also involve people from local power stations during demonstration and widespread dissemination.

Methodology & Reach

| Boiler Performance Optimisation | Predictive maintenance system and technologies for diagnostics |

| Best practices for air-preheater, etc. condenser water pressure cleaner | Reliability Centred Maintenance |

| Condenser helium leak detection | Thermodynamic modeling: A tool for performance analysis |

| Steam turbine performance assessment & optimisation | Thermal audit for accurate assessment of degradations |

| Real time measurements & balancing of air-fuel ratio | Risk Evaluation & Prioritisation |

| Cooling tower, condenser performance optimisation | New overhaul practices |

| Online CW flow measurement |

Partners

Inaugurated by the US Energy Secretary in 1994, CenPEEP has grown into a pioneering national resources centre for introduction of several cost-effective technologies for performance optimisation of power plants and environmental protection in the Indian thermal power sector. CenPEEP receives technical support for capacity building from US Agency for International Development (USAID) through U.S. Department of Energy’s (USDOE), National Energy Technology Laboratory (NETL), Electric Power Research Institute (EPRI), Structural Integrity Associates (SI), General Physics, utilities such as Tennessee Valley Authority (TVA), Reliant Energy, Mirant Corporation and US utility organisations such as EPRI, US Energy Association (USEA), etc. CenPEEP has a unique management structure consisting of an advisory board and an executive committee. With this structure, it is ensured that initiatives are relevant to meet sectoral needs.

In association with JICA and a consortium of Japanese utilities, a joint project was also taken up by CenPEEP for efficiency improvement where technologies such as pump efficiency assessment using Yates meter, leak buster test for air-in-leak quantification, simplified efficiency evaluations, evaluation of SUS scale, boiler simulation, have been demonstrated.

Impact

CenPEEP has demonstrated performance assessment techniques at all NTPC coal, gas stations along and 14 State Utilities stations. The tests have demonstrated heat rate improvement potential even in the best run power stations. Many of these demonstrated techniques and practices have been adopted by the stations. In NTPC alone, over 35 million tons of cumulative CO2 have been avoided since inception of CenPEEP activities through improvement in operating parameters. Some of the state utilities have acknowledged CenPEEP’s support in reducing their emissions by over 5.8 million tons in a year.

Some utilities have acknowledged CenPEEP contribution to their efficiency improvement in submissions before regulators. In effect, it is the largest GHG emission reduction effort in power utilities in India. CenPEP has developed ‘Heat Rate Improvement Guidelines’ jointly with TVA and circulated it to all the coal based power stations in India.

The CenPEEP also organises workshops / training programmes to NTPC and other power utilities for competency building of power sector professionals.

Participant in Asia Pacific Partnership (APP) on Clean Development and Climate

The Ministry of Power (Government of India) and Central Electricity Authority (CEA) have recognised NTPC/CenPEEP as an important agency involved in GHG reduction efforts and the success achieved in this area. Therefore they have entrusted CenPEEP with technology demonstration activities in Indian utilities under the APP multilateral programme. Through demonstration of performance assessment technologies in 3 state utilities, substantial CO2 savings have accrued at the 3 Stations of state utilities and an annual potential of over 300,000 tons of CO2 reduction has been identified.